Working principle.

Natural air heating unit composed of spin flash dryer inlet with suitable blowing speed from the bottom of dryer annular gap into the mixing and crushing and drying chamber, generating strong shear, blowing floating, rotating effect on enters from the feed inlet of the wet material, so the material by centrifugation, shear, collision, friction and by the particle, forming a large specific surface area, to enhance the mass and heat transfer effect of drying in the drying chamber, bottom, cluster large and damp in the mixer under the action of being broken into mechanical force, moisture content is low, particle size smaller particles, with air entrainment rotation rising, further drying and refinement on the rise in the process, after drying the product discharge through a cyclone separator, dust tail gas discharged into the atmosphere by pulse bag filter dust after.

Characteristic.

#9830; choose special feeder, keep feeding is continuous and stable, no bridge, arch, Baotuan phenomenon, especially suitable for viscous material.

#9830; wind device, reduces the resistance of the equipment, the drying chamber of wind speed and wind pressure evenly balanced.

#9830; the inner cone structure at the bottom of the drying chamber, unique structure of gas flow on the wall erosion and agitator, which can deal with a viscous material.

#9830; special gas seal and lubrication oil water cooling structure, effectively extending the service life of transmission parts.

#9830; drying chamber is provided with a classifier and a swirl plate, the size of material and the final moisture content can be controlled and adjusted.

#9830; drying chamber is arranged at the bottom of the water jacket cooling device, to avoid the material heated metamorphic phenomenon in the area of high temperature at the bottom.

#9830; dry indoor circumferential high gas velocity, short staying time of material, effectively prevent the wall sticking of materials and heat sensitive material deterioration.

#9830; overall equipment operating in the micro negative pressure operation, eliminating the pollution of the environment, the working environment clean and tidy, environmental protection standards.

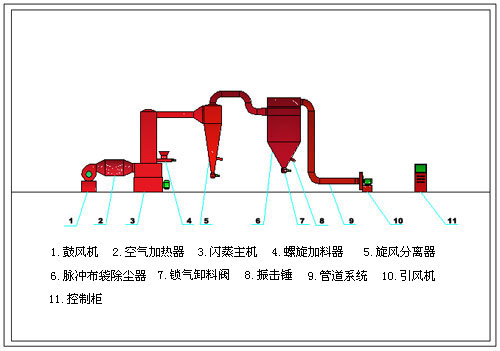

Sketch map.

技术参数:

| 型号 |

主机内径(mm) |

处理风量(m³/h) |

蒸发水分(Kg/h) |

装机容量(kw) |

主机高度(mm) |

| XSG-4 |

400 |

2100 |

80 |

16.2 |

4050 |

| XSG-6 |

600 |

4500 |

180 |

30.2 |

4300 |

| XSG-8 |

800 |

7500 |

300 |

51.5 |

4450 |

| XSG-10 |

1000 |

12000 |

480 |

83 |

5500 |

| XSG-12 |

1200 |

18000 |

720 |

100.7 |

6400 |

| XSG-14 |

1400 |

24000 |

960 |

129.05 |

7300 |

| XSG-16 |

1600 |

30000 |

1200 |

172.55 |

8200 |

| XSG-20 |

2000 |

42000 |

1680 |

230.55 |

10000 |

Note: 1, moisture evaporation air inlet temperature 200 ℃, outlet temperature of 80 ℃meter.

2, moisture evaporation, the installed capacity of basic data, according to the physicochemical properties of material change. |