Working principle.

Wet material conveyor and a heating unit natural air also enters the dryer, two full mixing, because the heat exchange area, so as to achieve the purpose of drying by evaporation in a very short period of time. After drying the product discharged from a cyclone, dust tail gas discharged into the atmosphere by pulse bag filter dust after.

QG type dryer is divided into: type ZQG ( positive pressure operation ), type FQG ( negative pressure ), JQG ( enhanced )

Characteristic.

#9830; dry strength, equipment investment: processing capacity of air drying equipment is the biggest, water evaporation capacity from 50kg/h-1500kg/h, and equipment investment, small volume, is unmatched by other drying equipment;

#9830; a high degree of automation, good quality of products: air drying material in the pipeline, the drying time is very short ( only 0.5-2 seconds ) so as to realize the automation, the product does not contact with the outside world, small pollution, good quality;

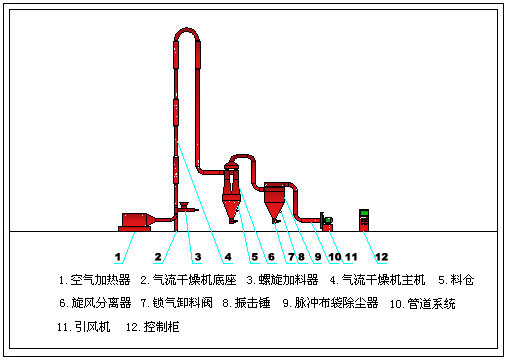

Sketch map.

技术参数:

| 型号 |

干燥管内径(mm) |

处理风量(m³/h) |

蒸发水分(Kg/h) |

装机容量(kw) |

| QG-150 |

150 |

1300 |

50 |

5.85 |

| QG-200 |

200 |

2300 |

90 |

9.7 |

| QG-250 |

250 |

3500 |

140 |

13.2 |

| QG-300 |

300 |

5100 |

200 |

17.6 |

| QG-350 |

350 |

7000 |

280 |

24.6 |

| QG-400 |

400 |

9000 |

360 |

33 |

| QG-450 |

450 |

11500 |

460 |

40 |

| QG-500 |

500 |

14100 |

560 |

41.5 |

| QG-600 |

600 |

20300 |

810 |

60.2 |

| QG-700 |

700 |

27700 |

1100 |

81.6 |

| QG-800 |

800 |

36200 |

1450 |

116.6 |

| QG-900 |

900 |

45800 |

1830 |

116.6 |

| QG-1000 |

1000 |

56500 |

2260 |

193.2 |

Note: 1, moisture evaporation air inlet temperature 200 ℃, outlet temperature of 80 ℃meter.

2, moisture evaporation, the installed capacity of basic data, according to the physicochemical properties of material change. |