Working principle.

The surface wet materials into a drier top small heating plate at the inner edge of the top of the drying machine feeding opening, in effect turning rake leaves, while turning and stirring, aside from the outside edge of inner heating plate in spiral movement, the material is formed in the disk of a plurality of cross section in the ring zigzag, materials to be dried by the the heating medium heating of the heat conduction of the disk after warming, drop by small heating plate edge to the next layer of large heating plate edge on the surface, in the reverse installation of the rake leaves driven by the market, the material outer edge of the spiral inward movement, and from the inner edge drop to the next layer of small heating plate edge on the disk, so internal and external alternating layers, material movement from top to bottom, gradually by heating and drying, and finally in the next layer of the heating disc harrow leaf to blow dryer by discharging port at the bottom of a continuous discharge, become dry product qualified, vaporization of the moisture from the dryer top outlet from natural or induced by induced draft fan. Small heating plate inside a cofferdam to make the material not to fall down from the small margin, high heating disc rim has a cofferdam to make the material not to fall down from the outer edge of the market, operating in the dryer spindle is driven by a motor, together with the fixed on the main shaft and the rotating harrow rake arm of Ye Yiqi.

Characteristic.

#9830; regulation is simple, strong applicability

The drying process can reach the best state by adjusting the thickness, spindle speed, the number of rake arm, harrow leaf number, leaf shape and size of material rake.

Each layer of the drying plate can be separately into the medium heat or cold medium, the heating or cooling materials, the material temperature control is accurate and simple.

Residence time of materials can be accurately adjusted.

A single flow of materials, no back-mixing phenomenon, even drying, stable quality, no longer mixed.

Simple operation, easy #9830;

Dryer boot, shutdown operation is very simple.

Stop feeding, rake leaves can quickly drain in the drying material.

Through the inspection door mirror, can be dried in the equipment and material were observed on the cleaning equipment.

#9830; low energy consumption

The material layer is very thin, the spindle speed is low, power material delivery needs of small, low power consumption.

To heat drying, high thermal efficiency, low energy consumption.

#9830; good operating environment, recyclable solvent, dust emissions to meet the requirements

Atmospheric pressure type: due to equipment and low flow velocity, humidity distribution equipment in low end, dust is difficult to float to the top of the tail gas equipment, so the top row of wet discharged almost no dust.

Closed type: equipped with solvent recovery device, easy to recycle the organic solvent in the wet gas, solvent recovery device has the advantages of simple structure, high recovery rate, the inflammable, explosive, toxic and readily oxidizable material, nitrogen can be used as moist-carrier gas closed cycle, so that the safe operation, especially suitable for flammable, explosive, toxic and easy oxidation drying.

Vacuum type: disc dryer operating in a vacuum state, especially suitable for heat-sensitive materials drying.

#9830; convenient installation, small occupation area

Dryer factory as a whole, the overall transport, only need hoisting, installation convenience.

The dryer dry-type layout, vertical installation, so that the drying area is large and small occupation area.

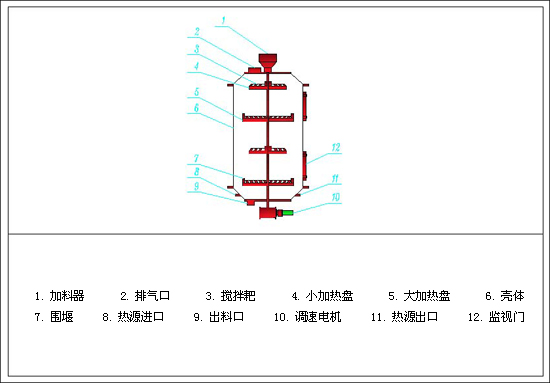

Sketch map.

技术参数:

|

规格 |

外径(mm) |

高度(mm) |

干燥面积(m²) |

装机容量(kw) |

|

1200/4 |

1850 |

2608 |

3.3 |

1.1 |

|

1200/6 |

3028 |

4.9 |

|

1200/8 |

3448 |

6.6 |

1.5

|

|

1200/10 |

3868 |

8.2 |

|

1200/12 |

4288 |

9.9 |

|

1500/6 |

2100 |

3022 |

8.0 |

2.2 |

|

1500/8 |

3442 |

10.7 |

|

1500/10 |

3862 |

13.4 |

|

1500/12 |

4282 |

16.1 |

3.0 |

|

1500/14 |

4702 |

18.8 |

|

1500/16 |

5122 |

21.5 |

|

2200/6 |

2900 |

3262 |

18.5 |

3.0 |

|

2200/8 |

3682 |

24.6 |

|

2200/10 |

4102 |

30.8 |

|

2200/12 |

4522 |

36.9 |

4.0 |

|

2200/14 |

4942 |

43.1 |

|

2200/16 |

5362 |

49.3 |

5.5 |

|

2200/18 |

5782 |

55.4 |

|

2200/20 |

6202 |

61.6 |

|

2200/22 |

6622 |

67.7 |

7.5 |

|

2200/24 |

7042 |

73.9 |

|

2200/26 |

7462 |

80.0 |

|

3000/8 |

3800 |

4050 |

48.0 |

11.0 |

|

3000/10 |

4650 |

60.0 |

|

3000/12 |

5250 |

72.0 |

|

3000/14 |

5850 |

84.0 |

|

3000/16 |

6450 |

96.0 |

|

3000/18 |

7050 |

108.0 |

13.0 |

|

3000/20 |

7650 |

120.0 |

|

3000/22 |

8250 |

132.0 |

|

3000/24 |

8850 |

144.0 |

|

3000/26 |

9450 |

156.0 |

15.0 | |